April 4, 2017

- Details

- Hits: 5707

WPC joins Viva Energy in charity even

WPC and Viva Energy have donated $8000 to Very Special Kids

Every year people from nearly 100 countries unite to do good deeds for others as part of globally acclaimed Good Deeds Day.

Between Monday 27 March and Sunday 2 April more than 750 Viva Energy employees across Australia donated over 650 hours to participate in 1,100 good deeds. As part of the fundraising efforts, WPC joined Viva Energy and together donated $8000 to Very Special Kids.

Very Special Kids cares for children with life-threatening conditions by providing a children’s hospice and professional family support services.

December 2, 2016

- Details

- Hits: 5057

WPC will deliver Della Foglia Ball Valves with Bettis Actuation to the Jemena Northern Gas Pipeline Project

WPC has succesfully tendered for the Mainline Actuated and Manual Valve package for the upcomming Jemena Northern Gas Pipeline Project.

The 622km pipeline will link Tennant Creek in the Territory to Mt Isa in Queensland, driving commercial exploration and development of currently untapped gas reserves, unlocking the next phase of economic growth for the Territory and helping build a stronger Northern Australia. Western Process Controls will be delivering large and small bore, 100% Italian, Della Foglia forged ball valves, locally integrated in the WPC Hallam Service Centre with Bettis actuation.

September 8, 2016

- Details

- Hits: 4109

Emerson awarded Shell Prelude contract

Shell Australia has chosen Emerson and its local business partner Western Process Controls to provide automation maintenance and reliability services for Shell’s Prelude Floating Liquefied Natural Gas (FLNG) facility.

The size of six aircraft carriers, Prelude is the world’s largest floating production facility. It will process natural gas collected from subsea wells 475 kilometers (almost 300 miles) offshore from Broome, Western Australia.

Since 2010, Emerson has served as Main Automation Contractor on the Prelude project, responsible for process control and monitoring technologies that will help Shell operate Prelude FLNG safely and efficiently. Under the new multi-year support contract, Emerson experts working both onshore and offshore will provide ongoing reliability and maintenance services for an even broader range of equipment.

Emerson and its local business partner, Western Process Controls, will provide equipment monitoring, diagnostic services, spares support, and maintenance for the facility’s control and safety systems, as well as thousands of instruments and valves.

Two expert Emerson engineers onboard Prelude will work with other team members who remotely monitor the facility’s automation from Shell’s operations center in Perth. The center’s high-tech Collaborative Work Environment will also enable the Emerson team to consult with Shell specialists as they use a proactive maintenance strategy to detect potential concerns, identify corrective actions, and arrange for delivery of any required equipment to the facility.

Prelude is under construction in Geoje, South Korea, before moving to Australia to begin operations. The facility is expected to remain on station at least 25 years as Shell and its partners develop gas reserves in the Browse Basin’s Prelude and Concerto fields.

For more on WPC's ability to help oil and gas producers optimize their operations, visit http://www.wpc.com.au/oil-and-gas

Photo courtesy of Shell.

November 2, 2016

- Details

- Hits: 4549

Main burner valves from Emerson help improve reliability and reduce operational expense for oil and gas processors

The Fisher™ Type 119EZ and 119EZS main burner valves provide variable opening speeds for proper ignition in pneumatic and automated burner systems

Emerson Automation Solutions has released the Fisher Type 119EZ and 119EZS main burner valves for burner systems used in oil and gas production. The new 119 Series can help improve oil and gas burner performance, increase reliability and reduce capital and operational expense.

The 119EZ provides an adjustable opening speed for pneumatically controlled burners while the 119EZS incorporates a solenoid valve enabling it to be used with automated burner systems. The 119EZ and 119EZS are designed with a built-in speed controller allowing the unit’s opening speed to be tuned to meet the burner design. Tuning the opening speed of the main burner valve to match the burner design, helps ensure proper ignition of the main burner. The opening speed can be adjusted from 3 seconds for smaller burners to 12 seconds for larger burners.

The units are designed to close in less than 3 seconds and provide Class VI shutoff. The integrated speed controller reduces installation cost associated with using an external speed controller. The 119EZ and 119EZS are retrofitable to existing burner systems in the field.

The Fisher Type 119EZ and 119EZS are based on the compact, field-proven, and reliable Fisher Type 119 control valve platform. The new main burner valve shares the same internals (diaphragm, disk, orifice, and springs) as the Fisher Type 119, which has been used for more than 25 years on burners in the oil and gas industry.

“The design requirements of burner systems provided a great opportunity for the engineering team to develop new technology that improves the tuning process and helps simplify customer installation,” said Thomas Weyer, director of upstream business, regulator technologies, Emerson Automation Solutions. “By integrating an adjustable orifice to our valve we allow our customers to precisely tune the valve opening speed. Utilizing feedback from the field, we were able to optimize the performance to create a product that meets all of our customers’ needs.”

For more information, please read the white paper.

July 22, 2016

- Details

- Hits: 4150

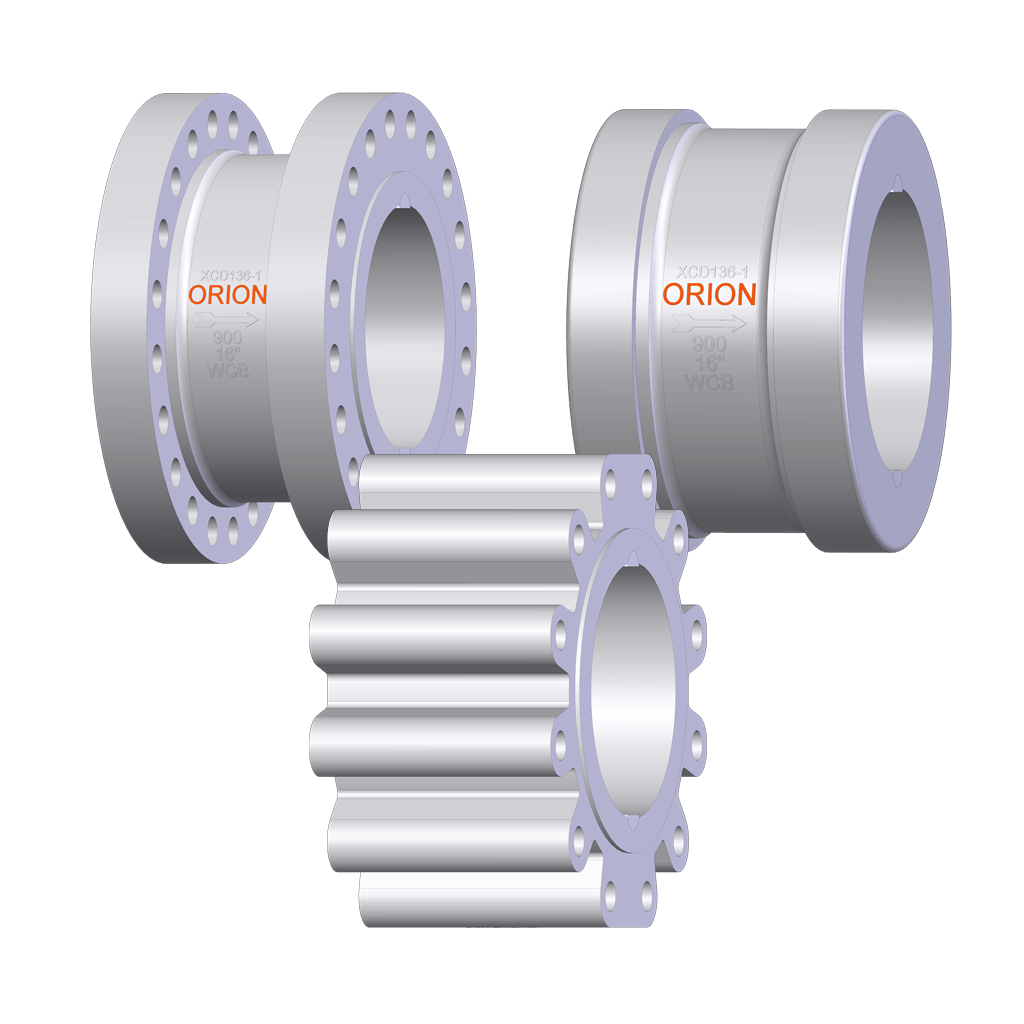

Orion API594 Dual Plate Check Valve

Orion has released a new API594 Dual Plate Check valve, suitable for Oil and Gas, chemical and other downstream industries. Available in wafer, lugged, double flanged or welded end design.

The body is realized in cast or forged steel, carefully designed in order to minimize the pressure drop. The basic dimensions, wall thickness, face to face and flanges, comply with the relevant API and ASME standards. Two guides are incorporated to ensure correct alignment of the hinge pin. The integral seat is part of trim Special attention is given to the seating surface which is ground and lapped, for a perfectly tight seal. The total absence of through-body drills (retainerless design) avoids any possible accidental leakage from the system.