- Details

- Hits: 13336

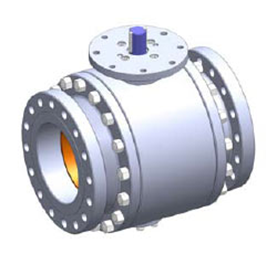

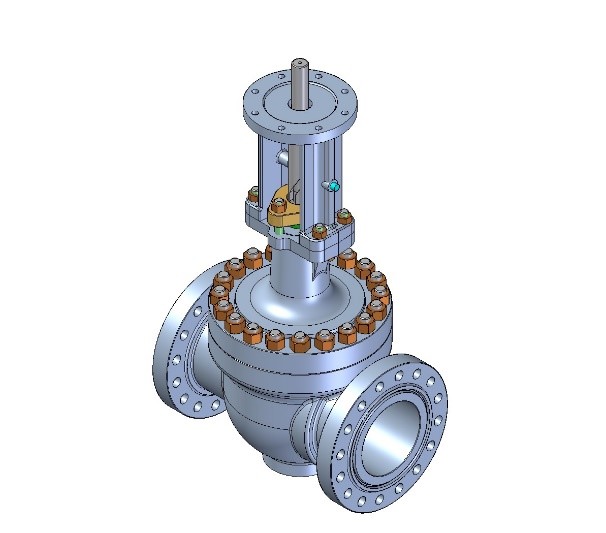

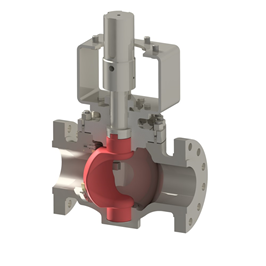

Ball Valves

A Ball Valve is a quarter-turn rotational motion valve with a straight through design that uses a ball-shaped disk to stop or start flow. If the valve is opened, the ball rotates to a point where the hole through the ball is in line with the valve body inlet and outlet. If the valve is closed, the ball is rotated so that the hole is perpendicular to the flow openings of the valve body and the flow is stopped. Ball valves can be found in a number of different styles. Some of these include one-piece, two-piece, three-piece and lastly, what is referred to as flanged body construction. Each form of ball valve has its own good and bad points, all dependent on what each application calls for. Ball valves are made using an assortment of materials, some of which include brass, bronze, cast iron, copper ductile iron, metal alloys, stainless and other steel types, and plastics (including CPVC and PVC). Ball valves are to be found being used in a number of different industries. Some of these include the chemical, oil, pharmaceutical, allied process and also services such as corrosive, abrasive and cryogenic.

- Subsea Ball Valves

- Double Block and Bleed Ball Valves

- Floating Ball Valves

- Trunnion Ball Valves

- Rising Stem Ball Valves

- Cryogenic Service

- Details

- Hits: 13463

Subsea Valves

Subsea Valves are used in sub-marine environments and forms an important part of a subsea flow infrastructure that can be installed in depths from shallow water usually down to a depth of 30 meters to deep water to a depth down to 4000 meters. Various industries use subsea valves with the oil, sea and gas sectors accounting for the majority of applications. Given the extreme external environmental factors that can be encountered at these depths, the consideration for subsea valves, over regular land based valves include, waterproofing, increase in ambient pressure measured in decibars (dbar) and construction materials that are able to withstand long-term corrosion effects from high salt content seawater.

Subsea Isolation

WPC represents ATV (Advanced Technology Valves) that provides a range of Subsea Isolation valves and actuators to the oil and gas offshore industry, with a focus on subsea applications. Products include gate, ball, and check valves in sizes from 0.5-in. (1.3-cm) up to 48-in. (1.2 m) and larger, in pressure classes up to 15,000 psi and 20,000 psi (1,034/1,379 bar).

Subsea Control

WPC represents KOSO Kent Introl Subsea Control Valves that covers a wide range of applications including single or multi-phase production, water/chemical/gas injection, artificial gas lift, anti-surge or closed loop flow control. All control valves and chokes can be provided as non-retrievable or insert retrievable designs. The range is complemented by a full suite of onshore and offshore handling, test and intervention equipment which can be packaged to meet project requirements and be provided on a rental or purchase basis.

- Details

- Hits: 13913

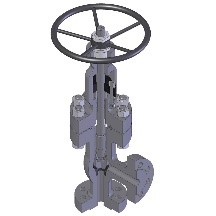

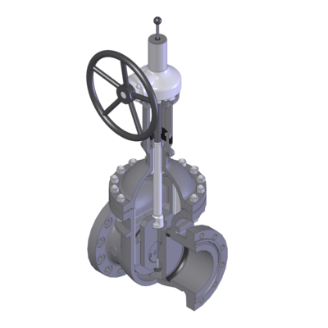

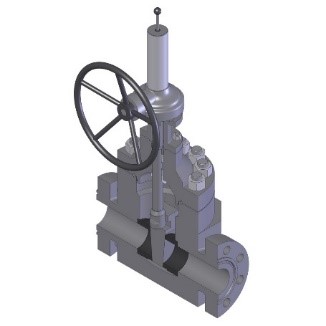

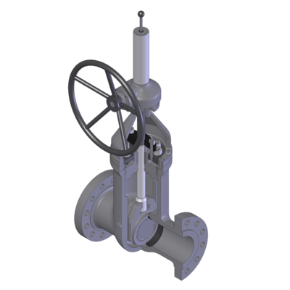

Gate Valves

Gate valves are primarily designed to isolate or fully pass flow through the valve, and when a flow of fluid with a minimum flow restriction are needed. In service, these valves generally are either fully open or fully closed. The design of a gate valve is such that the disk is completely removed when the valve is fully open leaving an opening the same size as the inside diameter at the pipe in which the valve is installed.

- Details

- Hits: 9602

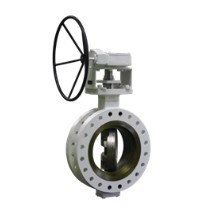

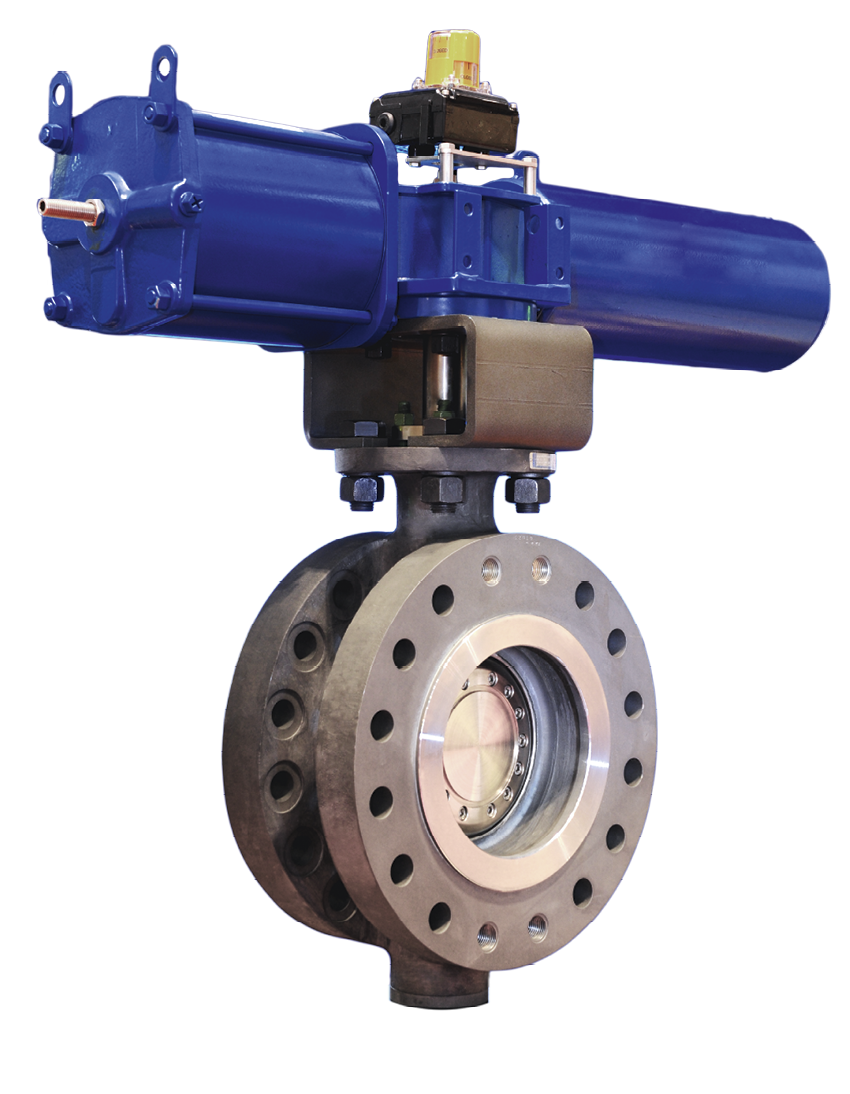

Butterfly Valves

A Butterfly valve is a quarter-turn rotation valve, that is used to regulate flow in a piping system. Butterfly valves are fast and easy to open and a 90° rotation of the disk provides a complete isolation or fully open position of the valve. Butterfly valves main advantages is the weight and space saving over gate, globe, plug, and ball valves. The maintenance costs is reduced because there are a minimal number of moving parts. Typical Butterfly valves applications are for the control or isolation of large flows of liquids or gases at relatively low pressures and for the handling of slurries or liquids with large amounts of suspended solids.

- Centre Line Pattern

- Double Eccentric Pattern

- Three Eccentric Pattern

- Resilient Seated Valves

- Details

- Hits: 8216

Globe Valves

A Globe valve is a linear valve and is primarily designed to isolate or start flow. Shut-off is accomplished by moving the disc against the flow stream rather than across it as in the case with a gate valve. Globe valves normally have a slightly higher pressure drops than straight through valves (e.g., gate, plug, ball, etc.), they may be used where the pressure drop through the valve is not a controlling factor. Globe valve is considered uni-directional and must be installed with the pressure side or inlet under the seat.